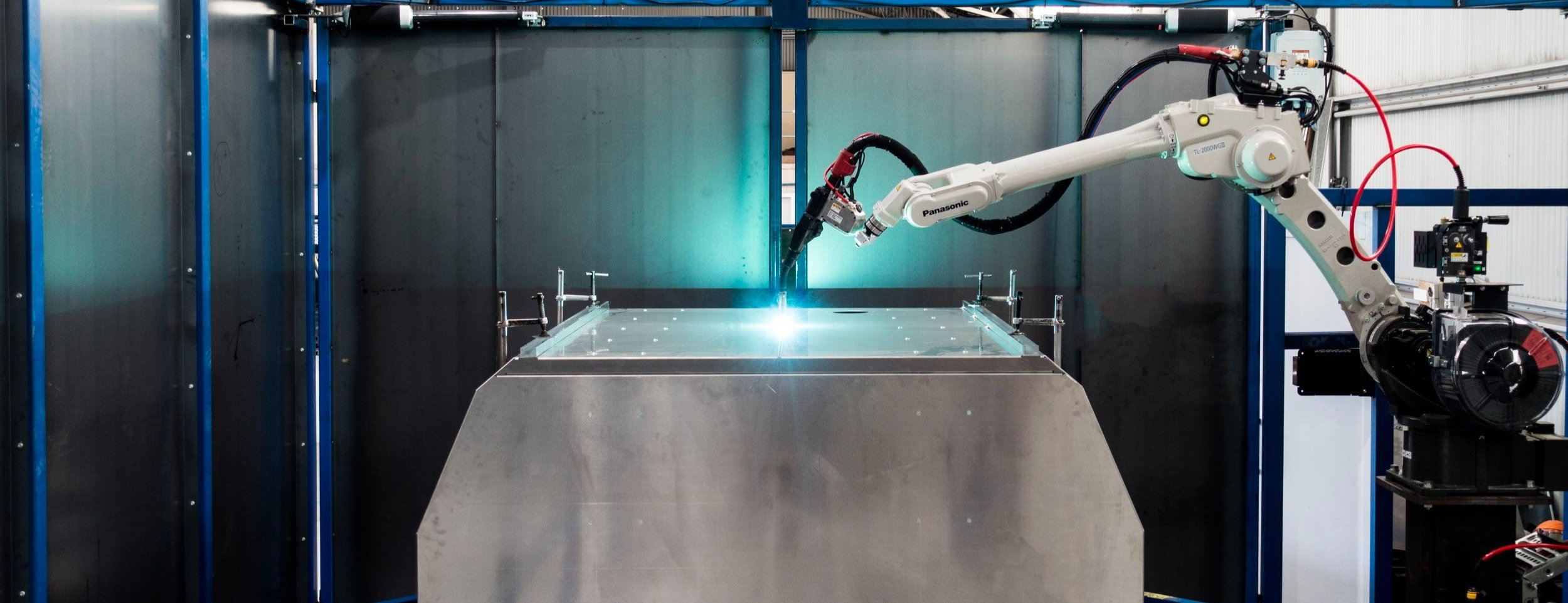

Dual station robotic welding cells

Versatile & Highly Productive robotic welding cells

Versatile, powerful, and engineered for performance. Orion’s dual station robot welding cells bring Panasonic’s 45+ years of welding robotics expertise to Australian and NZ manufacturers

Optimised cell access for easy operation and loading

Loading and unloading of large parts or jigs is simple with a large cell entrance, and a steel sliding door for side access for programming and maintenance.

Dual station design increase robot arc-on time

With 2 stations for the robot to operate, the robot is able to work in one station while your operator reloads on the other side.

Highly capable, fully integrated robots designed for welding.

Using Panasonic’s dedicated welding robot manipulators and integrated welding power source, and options for MIG or TIG, this system is flexible to suit your specific needs.

Smart, practical designs

Using our in-house designs for solid steel guarding, pedestals, and rotator interfaces, our cells are installed fast and clean

Options for part positioning with fixed tables or integrated rotators

With an option for rotating tables up to 2000kg capacity, it’s possible to weld complex components.

It’s also possible to add a 2-axis positioner to allow for even more comprehensive part manipulation for complex parts with difficult areas to reach.

Rotators also save time and increase safety for operators, letting the robot perform manipulation of heavy parts into their best welding orientations.

Modular, relocatable jigging solutions

Orion’s table and rotator locator designs allow for the easy removal and quick exchange of jigging, ensuring that parts are located accurately the next time you install a jig.

What’s included:

Panasonic TM or TL series robot arm with 1400mm, 1800mm, or 2000mm of reach

Panasonic’s G4 robot controller with integrated 350A or 500A power source

Servo-controlled wire feed system

Panasonic MIG or TIG torch

Panasonic’s dedicated welding programming teach pendant

Machined mild steel pedestal and master jig table with locator guides

Full steel guarding: RHS posts, sheet panels, and access door

Safety light curtains and controls designed to ISO and Australian Standards

Operator control stations for each work station

On-site installation

Jigging support

On-site training on Panasonic’s intuitive welding interface

Technical support from our experts with 35+ years’ experience

Direct supply of Panasonic consumables and spare parts through Orion

At Orion, we pride ourselves in providing standardised systems that cover a wide range of processes, materials and part sizes for your manufacturing needs.

We are 100% focused on robot welding

Orion Automation Systems maximises your production using high performance industrial robotic welding systems, and the ongoing technical support to keep you in production for years to come.

Real Robots.

Real Experience.

Real Speed.

Real Productivity.

Options & Additions:

We are able to offer a wide range of options and technologies in addition to the base system, assisting in part manipulation, weld location tracking, and much more

These options include:

Single or Multi Axis Positioner Systems with payload capacity from 250 kg to 10,000 kg

Panasonic’s DTPS Off Line Programming Software

Part locating technologies such as touch sensing or laser seam tracking

Panasonic Process Control and production management software packages

On-torch fume extraction for MIG welding

Tool change systems